Simultaneous Firing Solutions for Waste Fuel Streams

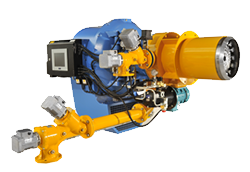

Dunphy has developed a range of solutions for safe and efficient co-firing of fossil fuels, liquid bio fuels and gaseous fuels derived from recovered waste sources.

Bio and waste fuels are characterised by variable availability and inconsistent calorific values. Quite often these fuels can be burnt on their own but in many cases require a base fuel to be fired simultaneously. TheDunphy Ratiotronic 6009 system allows a bio/waste fuel stream to be fired together with a base fuel. This could be two liquid fuels, two gaseous fuels or a combination of the two. Combustion head design is critical to ensure complete combustion of the fuel mixture whilst maintaining ultra low excess oxygen levels.

An external 4-20mA signal is used as a waste fuel availability signal and indicates the amount of waste fuel which is available at any one time. There is no restriction on the amount of waste fuel which can be burnt; it can vary from zero to the maximum firing rate of the burner. The control system will however ensure that all waste fuel is burnt before burning more expensive base fuels. An internal software algorithm controls the mix of the fuels and air to ensure combustion is optimised whilst maintaining safe combustion. Oxygen trim is an integral element of the control system using two zirconia oxygen probes. Combustion variables are continuously monitored and adjusted such that variations in calorific values or external environmental conditions do not compromise combustion efficiency or safety.

ATEX rated burner components are available for all aspects of the burner and we will be more than happy to help you with any hazardous area classifications.

Triple fuel options are also available, i.e. natural gas and bio gas firing simultaneously with a diesel oil backup . Burners are designed specifically to meet a customer need, if you have a waste fuel and would like to convert it to usable energy and save money in the process, please contact info@mckenzieservice.com